The opening and closing component of J41H cast steel globe valve is a cylindrical valve disc with a flat or conical sealing surface. The valve disc moves linearly along the centerline of the fluid. The national standard globe valve is only suitable for fully open and fully closed, and is generally not used to regulate flow. When customized, it is allowed to be adjusted and throttled. Suitable for cutting off or connecting media on pipelines in various working conditions such as petroleum, chemical, pharmaceutical, fertilizer, and power industries with a nominal pressure of PN1.6~16.0Mpa and a working temperature of -29~550 ℃. Applicable media include water, oil, steam, acidic media, etc. The operation modes include manual, gear transmission, electric, pneumatic, etc.

Working principle of J41H cast steel globe valve

J41H cast steel globe valve belongs to the forced sealing type valve. When the valve is closed, pressure is applied to the valve disc to force the sealing surface not to leak. When the medium enters the valve from below the valve disc, the resistance that the operating force needs to overcome is the frictional force between the valve stem and the packing, as well as the thrust generated by the pressure of the medium. The force required to close the valve is greater than the force required to open it, so the diameter of the valve stem should be larger, otherwise the valve stem bending fault may occur. In recent years, with the emergence of self sealing valves, the flow of medium in shut-off valves has shifted from above the valve disc into the valve chamber. Under the pressure of the medium, the force required to close the valve is small, while the force required to open the valve is large, resulting in a corresponding reduction in the diameter of the valve stem. Meanwhile, under the influence of the medium, this type of valve is also relatively tight. The flow direction of the shut-off valve shall be from top to bottom.

Main component materials and performance parameters of J41H cast steel globe valve

| Body/Cover/Plate | Stem | Sealing | Gasket | Filler | Temperature℃ | Medium |

|---|---|---|---|---|---|---|

| WCB | 2Cr13 | 13Cr ST |

1Crl3/Flexible graphite 0Cr18Ni9Ti OCr18Ni12Mo2Ti |

Flexible graphite SFB-260 SFP-260 |

≤425 | Water, steam, oil products |

| WC1 | 38CrMoAI 25Cr2MoV | ≤450 | ||||

| WC6 | ≤540 | |||||

| WC9 | ≤570 | |||||

| ZGCr5Mo | ≤540 | |||||

| ZG1Cr18Ni9Ti | 1Cr18Ni9Ti | ≤200 | Nitric acid | |||

| ZGCr18Ni12Mo2Ti | 1C18Ni12Mo2Ti | ≤200 | Acetic acid |

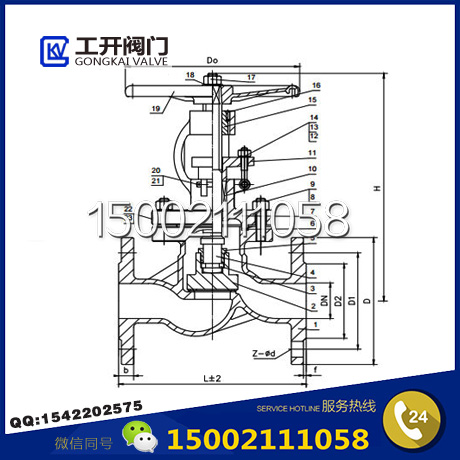

Main appearance and connection dimensions of J41H cast steel globe valve

| 1.6MPa | DN | L | D | D1 | D2 | b | n-Φd | H | D0 |

|---|---|---|---|---|---|---|---|---|---|

|

RF J41H J41Y J41W J41F J41N 16C 16P 16R 16I |

10 | 130 | 90 | 60 | 40 | 14 | 4-Φ14 | 198 | 120 |

| 15 | 130 | 95 | 65 | 45 | 14 | 4-Φ14 | 218 | 120 | |

| 20 | 150 | 105 | 75 | 55 | 14 | 4-Φ14 | 258 | 140 | |

| 25 | 160 | 115 | 85 | 65 | 14 | 4-Φ14 | 275 | 140 | |

| 32 | 180 | 135 | 100 | 78 | 16 | 4-Φ18 | 280 | 160 | |

| 40 | 200 | 145 | 110 | 85 | 16 | 4-Φ18 | 330 | 180 | |

| 50 | 230 | 160 | 125 | 100 | 16 | 4-Φ18 | 350 | 200 | |

| 65 | 290 | 180 | 145 | 120 | 18 | 4-Φ18 | 370 | 280 | |

| 80 | 310 | 195 | 160 | 135 | 20 | 8-Φ18 | 400 | 280 | |

| 100 | 350 | 215 | 180 | 155 | 20 | 8-Φ18 | 415 | 320 | |

| 125 | 400 | 245 | 210 | 185 | 22 | 8-Φ18 | 460 | 360 | |

| 150 | 480 | 280 | 240 | 210 | 24 | 8-Φ23 | 510 | 450 | |

| 200 | 600 | 335 | 295 | 265 | 26 | 12-Φ23 | 710 | 500 | |

| 250 | 650 | 405 | 335 | 320 | 30 | 12-Φ25 | 786 | 550 | |

| 300 | 750 | 460 | 410 | 375 | 30 | 12-Φ25 | 925 | 600 |

| 2.5MPa | DN | L | D | D1 | D2 | b | n-Φd | H | D0 |

|---|---|---|---|---|---|---|---|---|---|

|

RF J41H J41Y J41W J41F J41N 25C 25P 25R 25I |

10 | 130 | 90 | 60 | 40 | 16 | 4-Φ14 | 198 | 120 |

| 15 | 130 | 95 | 65 | 45 | 16 | 4-Φ14 | 218 | 120 | |

| 20 | 150 | 105 | 75 | 55 | 16 | 4-Φ14 | 258 | 140 | |

| 25 | 160 | 115 | 85 | 65 | 16 | 4-Φ14 | 275 | 140 | |

| 32 | 180 | 135 | 100 | 78 | 18 | 4-Φ18 | 280 | 160 | |

| 40 | 200 | 145 | 110 | 85 | 18 | 4-Φ18 | 330 | 180 | |

| 50 | 230 | 160 | 125 | 100 | 20 | 4-Φ18 | 350 | 200 | |

| 65 | 290 | 180 | 145 | 125 | 22 | 8-Φ18 | 400 | 280 | |

| 80 | 310 | 195 | 160 | 135 | 22 | 8-Φ18 | 355 | 280 | |

| 100 | 350 | 230 | 190 | 160 | 24 | 8-Φ23 | 415 | 320 | |

| 125 | 400 | 270 | 220 | 188 | 28 | 8-Φ25 | 460 | 360 | |

| 150 | 480 | 300 | 250 | 218 | 30 | 8-Φ25 | 510 | 450 | |

| 200 | 600 | 360 | 310 | 278 | 34 | 12-Φ25 | 710 | 500 | |

| 250 | 622 | 425 | 370 | 332 | 36 | 12-Φ30 | 786 | 550 | |

| 300 | 698 | 485 | 430 | 390 | 40 | 16-Φ30 | 925 | 600 |