Pipeline pneumatic valve, also known as pneumatic shuttle valve, pneumatic pipeline valve, etc. Pipeline pneumatic valves are mainly composed of cylinders, piston type valve seats, and valve cores. It is a two position pneumatic actuator used in conjunction with solenoid valves to achieve flow control during fluid transportation. Its working principle is to push the piston valve seat from the open position to the closed position or from the closed position to the open position by pushing it from the high pressure to the low pressure side according to the pressure of the gas source flowing into both sides of the piston. The pneumatic shuttle valve integrates its sealing mechanism with the control system, ensuring sensitive control performance. The optimized design ensures a service life of millions of times, making it an ideal equipment for industrial automatic control. Gas pipeline control systems widely used in industries such as petroleum, chemical, metallurgical, light industry, textile, and environmental protection.

ZSGP stainless steel pipeline pneumatic valve product features:

1. The actuator manufactured by integrating the piston and valve core has superior rigidity and stability.

2. During the opening and closing process, the sealing surface has good wear resistance and sealing performance.

3. The opening and closing stroke is small.

4. Can quickly complete the opening and closing action within (less than 0.3) seconds.

5. The fluctuation of pressure difference before and after the valve will not affect the opening and closing speed of the valve.

6. The valve action indication is intuitive, with feedback indicating.

7. Compact in appearance and structure, easy to install and maintain.

8. Easy for remote pneumatic control.

9. The service life of valves is up to 20 years, and the service life of seals (vulnerable parts) exceeds 2 million times

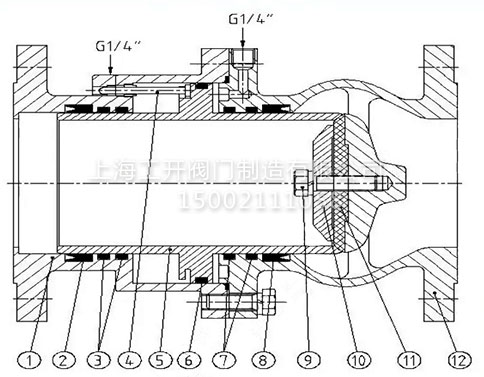

Structural diagram and main connection dimensions of ZSGP stainless steel pipeline pneumatic valve:

| DN | D | D1 | L | Φ-n | m-n |

| 20 | 105 | 75 | 150 | 4-Φ14 | M10×1 |

| 25 | 115 | 85 | 160 | 4-Φ14 | |

| 32 | 140 | 100 | 180 | 4-Φ18 | |

| 40 | 150 | 110 | 200 | 4-Φ18 | |

| 50 | 165 | 125 | 203 | 4-Φ18 | |

| 65 | 185 | 145 | 216 | 4-Φ18 | M12×1.25 |

| 80 | 200 | 160 | 241 | 4-Φ18 | |

| 100 | 220 | 180 | 292 | 4-Φ18 | |

| 125 | 250 | 210 | 330 | 4-Φ18 | |

| 150 | 285 | 240 | 356 | 4-Φ22 | |

| 200 | 340 | 295 | 495 | 4-Φ20 |