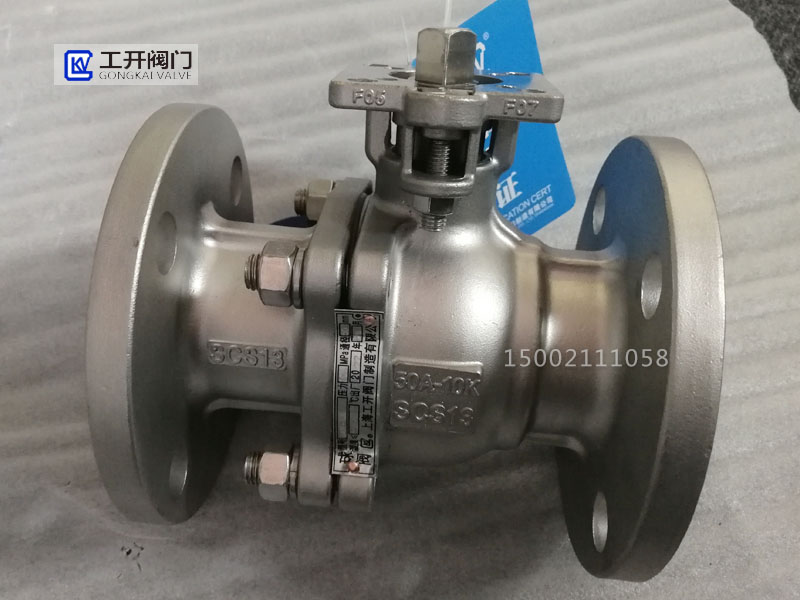

Flange Ball Valves法蘭球閥

2016/12/2 15:49:15

Introduction

Flange ball valve is a type of valve widely used in various industrial fields, characterized by compact structure, reliable sealing, and easy operation. The main components of a flanged ball valve include a ball and a valve seat, which are opened and closed by rotating the ball. The design of this valve makes it perform well in applications that require quick switching or fluid regulation. ?

Working principle: The working principle of flange ball valve is based on the rotational motion of the sphere. When the sphere rotates 90 degrees, the valve changes from the closed state to the open state, and vice versa. This design allows the flange ball valve to have less fluid resistance and fast switching operation. ?

Characteristics:

Simple structure: The structural design of the flange ball valve is simple, easy to maintain and repair. ?

Good sealing performance: The sealing surface material of the flange ball valve widely uses various plastics, which can achieve complete sealing and ensure effective control of the fluid. ?

Wide applicability: Suitable for various working media such as water, solvents, acids, and natural gas, especially suitable for harsh working conditions such as oxygen, hydrogen peroxide, etc. ?

Easy to operate: simply rotate 90 degrees to complete the opening and closing operations, making it convenient for remote control. ?

Application areas: Flange ball valves are widely used in industries such as petroleum refining, long-distance pipelines, chemical, papermaking, pharmaceuticals, water conservancy, power, municipal, and steel, and occupy an important position in the national economy. ?

In addition, there are various types of flanged ball valves, such as floating ball valves, fixed ball valves, and elastic ball valves, each with its specific application scenarios and advantages. For example, floating ball valves are suitable for medium and low pressure applications, while fixed ball valves are suitable for high pressure and large diameter applications. Elastic ball valves are suitable for high-temperature and high-pressure media, and better sealing effects are achieved through the design of elastic grooves

Working principle: The working principle of flange ball valve is based on the rotational motion of the sphere. When the sphere rotates 90 degrees, the valve changes from the closed state to the open state, and vice versa. This design allows the flange ball valve to have less fluid resistance and fast switching operation. ?

Characteristics:

Simple structure: The structural design of the flange ball valve is simple, easy to maintain and repair. ?

Good sealing performance: The sealing surface material of the flange ball valve widely uses various plastics, which can achieve complete sealing and ensure effective control of the fluid. ?

Wide applicability: Suitable for various working media such as water, solvents, acids, and natural gas, especially suitable for harsh working conditions such as oxygen, hydrogen peroxide, etc. ?

Easy to operate: simply rotate 90 degrees to complete the opening and closing operations, making it convenient for remote control. ?

Application areas: Flange ball valves are widely used in industries such as petroleum refining, long-distance pipelines, chemical, papermaking, pharmaceuticals, water conservancy, power, municipal, and steel, and occupy an important position in the national economy. ?

In addition, there are various types of flanged ball valves, such as floating ball valves, fixed ball valves, and elastic ball valves, each with its specific application scenarios and advantages. For example, floating ball valves are suitable for medium and low pressure applications, while fixed ball valves are suitable for high pressure and large diameter applications. Elastic ball valves are suitable for high-temperature and high-pressure media, and better sealing effects are achieved through the design of elastic grooves